CASE STUDY

Explosion Relief

THE CHALLENGE

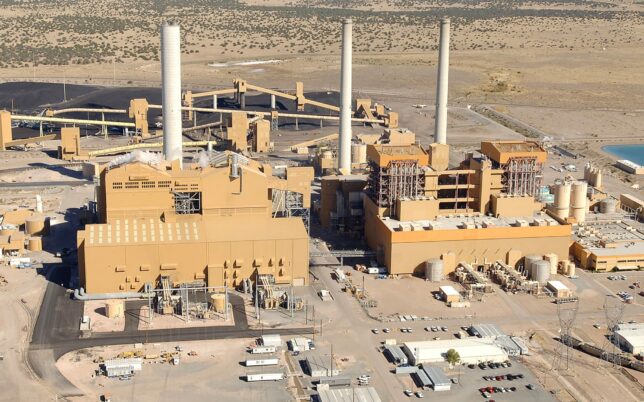

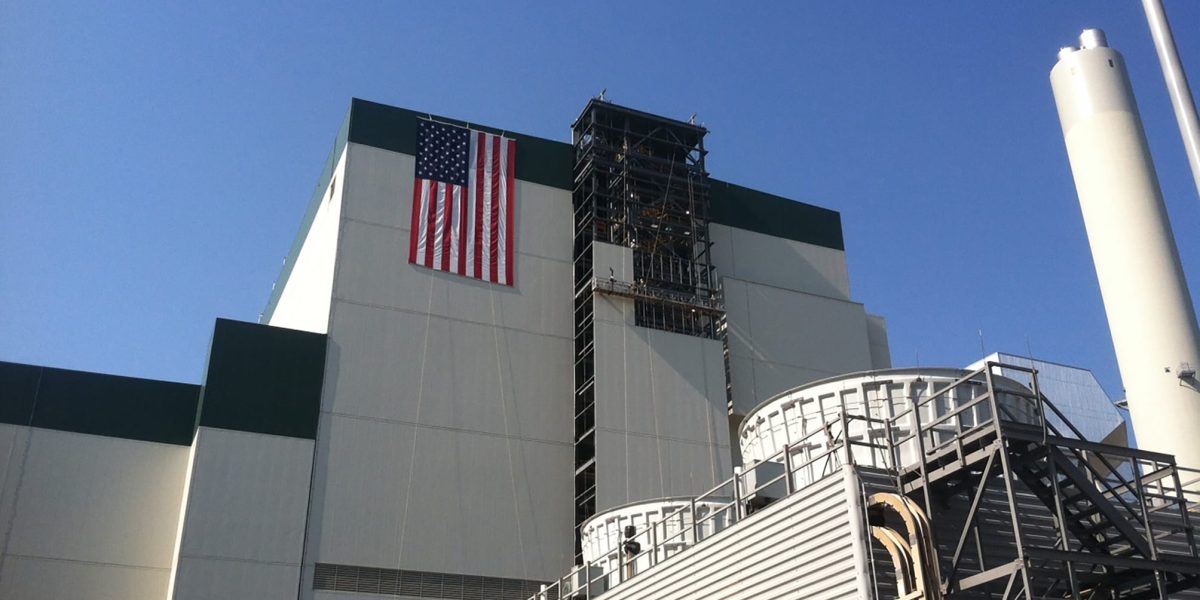

CSM contracted with CB&I/Shaw to supply and install the roofing and siding on a new power plant in Virginia. The design called for an area of explosion relief panels due to the possibility of the stored coal combustion.

The SCOPE

264,500 SF

of insulated metal roof and wall panels

138,600 SF

of single skin metal siding

10,000 SF

of explosion relief panels

The outcome

The explosion relief system we engineered consisted of our metal siding attached to the structural girts with stainless steel cable. Special fasteners are designed to release after being exposed to the pressures during an explosion. Not only does this system prevent the metal panels from becoming projectiles, but it also relieves the pressure – thus minimizing the explosion.

Other Case Studies

Remote Location

A 2-year power plant project was set 30 miles away from the nearest lodging. We had to think creatively to provide housing for our 20-men ...

Coordination

When a facility storing food-grade additives needed new roofing and siding, we had the task of doing the replacement while protecting the content from the ...